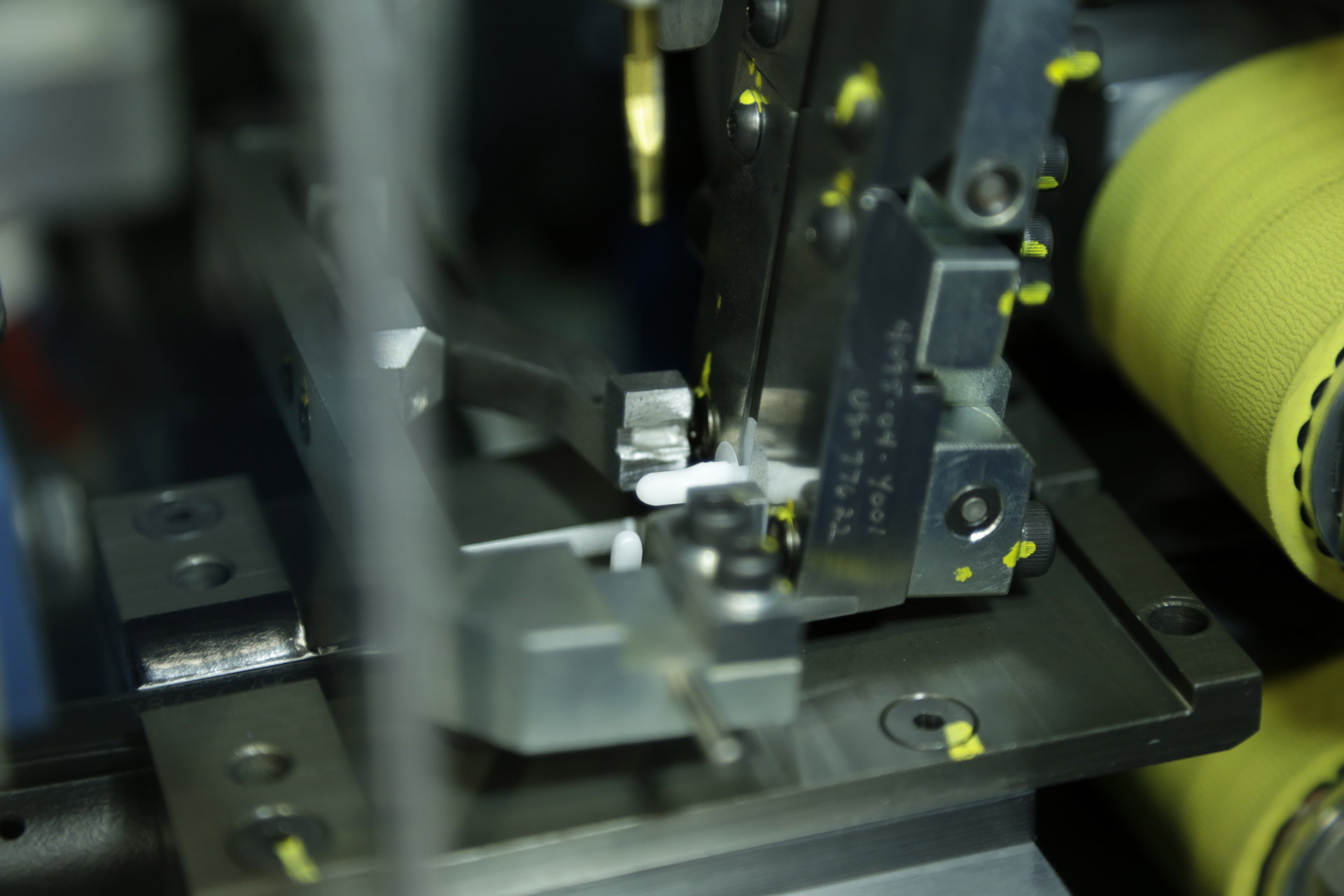

SPLICING PRESS

- Faster cycle

- Good sealing

- Good esthetic quality

- Lower processing cost

The system is used to obtain sturdy joints by inserting a sheet of non-vulcanised rubber of approx. 0.5 mm thick between two pre-heated moulds constructed according to the geometry of the profile to be sealed.

For improved quality, the moulds are produced for each individual profile configuration; in this manner, the joint is perfect from both the aesthetic and the mechanical viewpoint.

Type of joints :

The profiles to be sealed can be straight or angular and can be made of different materials:

- All rubber

- Rubber/sponge

- Reinforced rubber/sponge

- Hollow extruded items such as pipes

- Silicone type materials

TECHNICAL DATA

| Sealing cycle | 90 /100 s |