Accuracy and speed For all types of parts

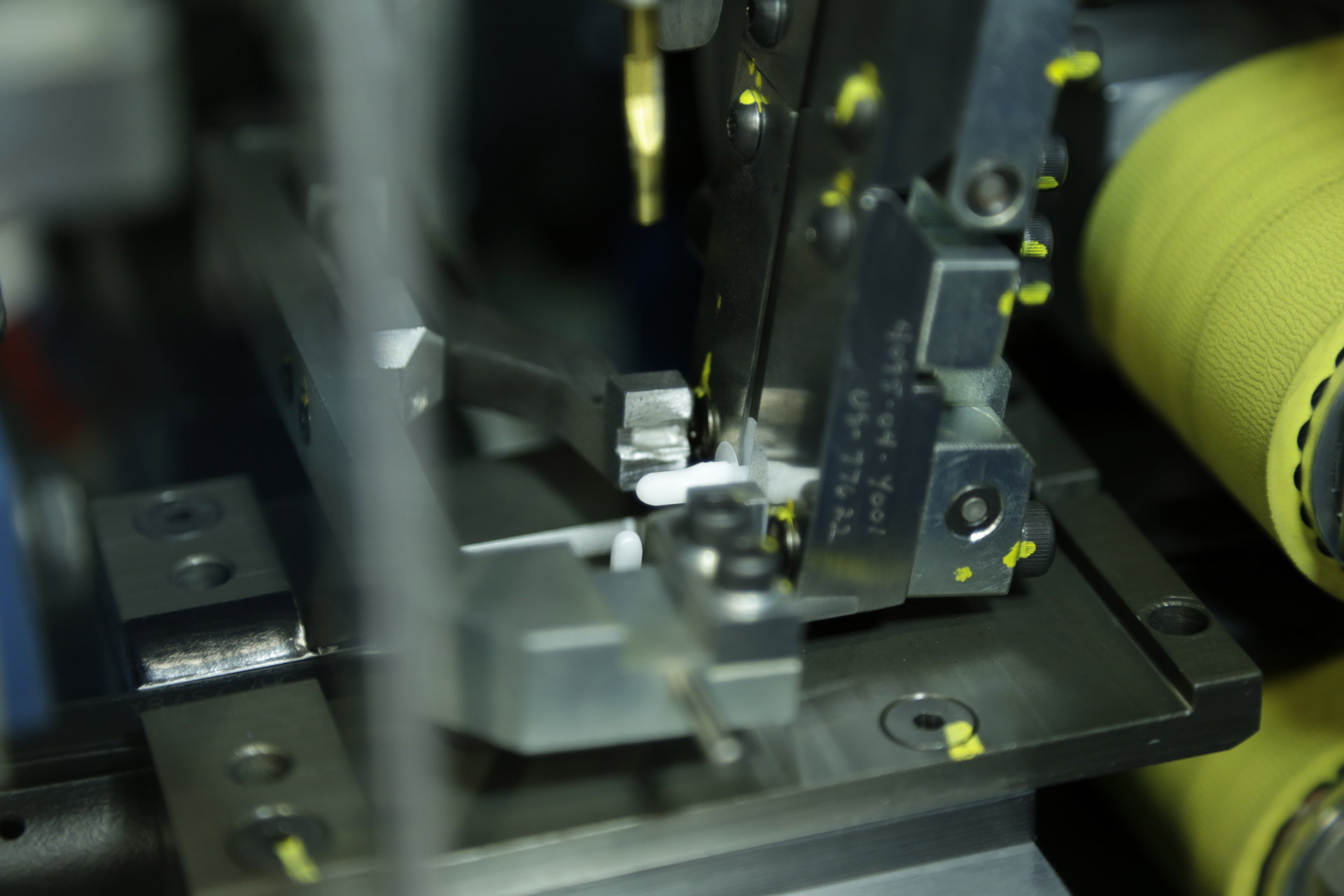

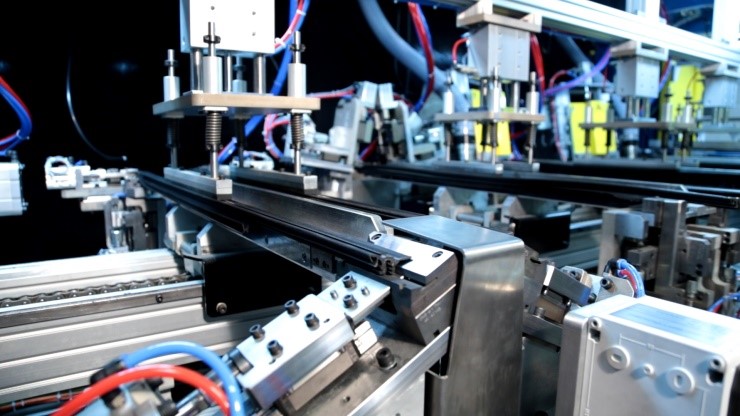

The automatic cutting bench was designed in order to achieve high production volumes as well as complex cuts for rigid parts such as Outerbelts, Innerbelts or Headers.

Quick and precise, it enables a single operator to produce complete parts (1 LH and 1 RH) with a cycle-time of 30 to 45 seconds on a shuttle type bench and 10 to 15 seconds for a multi-pallet type bench. The fastest on the market! The integration of robots can make the production cell completely autonomous.

The unique design of the interchangeable tools enables the operator to switch from one program to another in less than 15 minutes, thus enabling our customers to split the cost of capital on several different projects and be more competitive on the world stage.

Components

- Simple and easy to use operator interface

- Quick interchangeability of tools using poke yoke system

- Camera inspection

- Inserting End caps in automatic mode

- Integration of robots for process automation

TECHNICAL DATA

| Cycle-time shuttle type bench (2 parts) | 30 to 40 s | |

| Cycle-time multi-pallet type bench (2 parts) | 10 to 15 s | |

| Cut tolerances | ± 0,4 mm | |

| Overall-length tolerance | ± 0,8 mm |