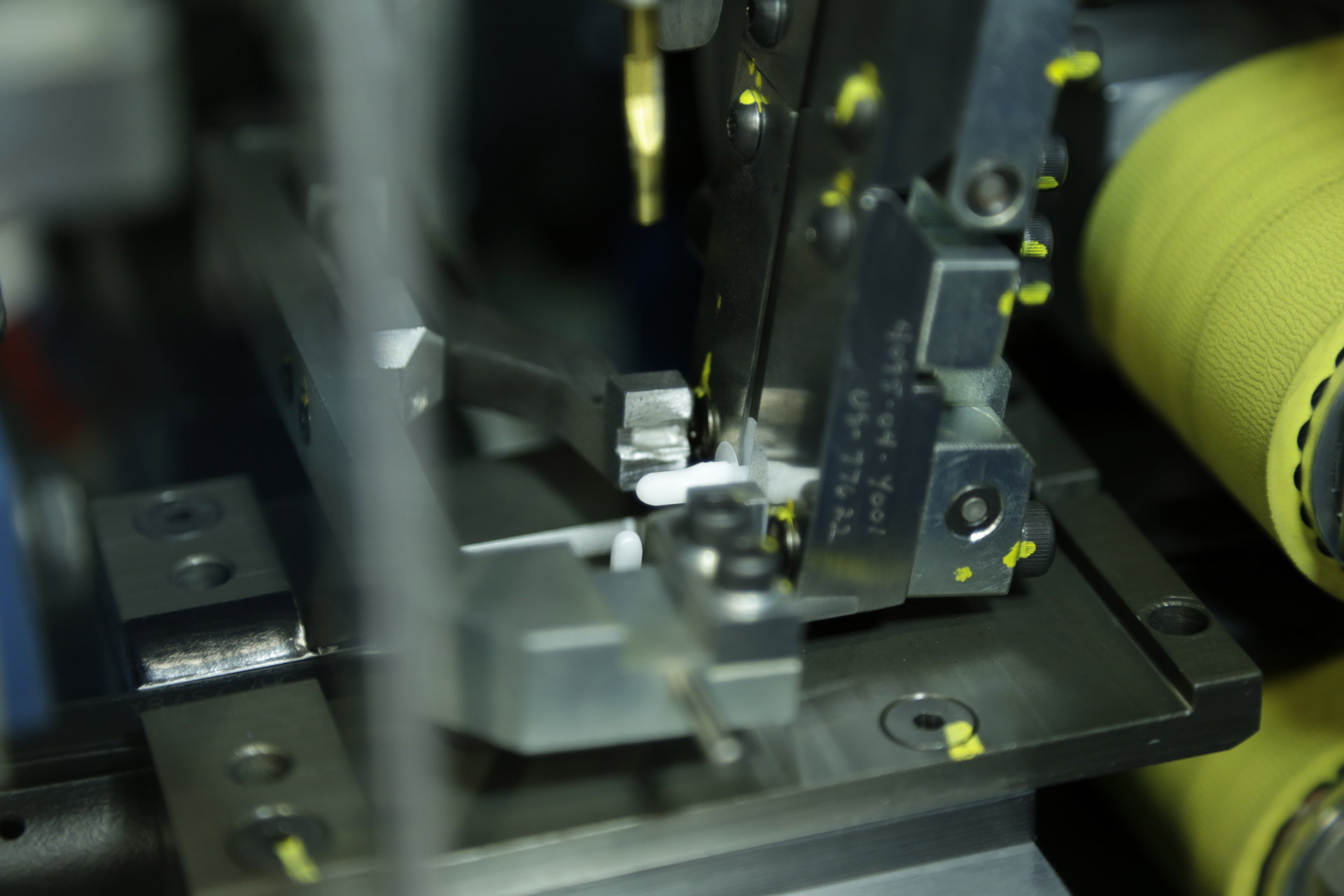

LASER DRILLING

Laser drill two heads

By making use of a special CO2 laser, we are now able to produce a sequence of drilling operations on an extrusion line, at a rate of up to 30 m/minute, to make air vent holes in profiles complete with a bulb. The term “holes” does not do justice to this machine, since in addition to drilling holes of different sizes, it is able to create vent cavities of various shapes: triangles, rectangles, slots, etc.

Advantages

- Making vent holes of different shapes, not only round ones

- Making vent holes without chips

- Making vent holes to meet different geometry and spacing requirements

- Applying identification marks between the holes

- Drilling holes simultaneously in two bulbs

- No downtime to change the drill bits